Originally posted January 25, 2017

Here's an odd one for you.

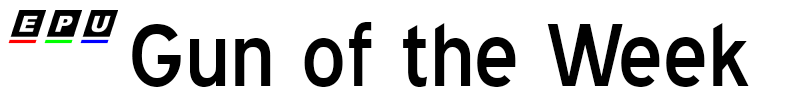

As you can probably tell from the photo, this is not an antique firearm. In fact, first on the market less than three years ago, the Walther CCP is undoubtedly the newest firearm in my collection just based on its design age, never mind manufacture date. It's a polymer-framed, striker-fired semiautomatic pistol of a thoroughly modern type, in this case finished in something called Cerakote (the other option was stainless steel, but I dunno, I think stainless slides look weird on black polymer-framed pistols).

Walther's marketing people have been giving their handguns three-letter code names for a while now, although in the CCP's case, they've gone back to actually standing for something. The fact that it's the initials of an English phrase (Concealed Carry Pistol) should tell you all you need to know about what market it's intended for. (To be fair, there aren't a lot of large civilian carry handgun markets left in the world nowadays.)

What we have here, then, is a small semiautomatic handgun, specifically designed and marketed for concealed carry, and chambered in 9mm Parabellum, that go-to full-power service pistol cartridge of the late-20th/early-21st century Western world. This makes it significantly more powerful than most other auto pistols of a similar size and weight, most of which tend to be in .380 ACP/9mm Short (with the exception of the very small Glocks, which as far as I know are still short-recoil locking).

Ordinarily, this would tend to make a handgun of that size pretty hard to manage. Eastern Bloc pistols like the Makarov and vz. 82, running the only-slightly-less-powerful 9mm Makarov, are pretty brutal on the operator's hand. Add to that the fact that the CCP does not have a locking action, but is instead a blowback design, and it all isn't sounding very promising. To operate safely in an unlocked blowback pistol of that size, so obviously limited in how heavy the slide can be, 9mm Para should require a recoil spring so robust as to make the thing almost inoperable by hand (similar to the Polish P-64).

Walther's engineers got around this by borrowing a trick from their competitors over at Heckler & Koch, who developed it in the '70s for the P7 (and hence the patents have expired). Walther calls it by the trademark name Softcoil® (because it supposedly also reduced perceived recoil, though I suspect the ergonomics of the grip have more to do with that), but mechanically it's known as a gas-delayed blowback system.

To get a look at how it works, we have to take the pistol apart, which is, let me just note now, not a straightforward and simple delight on par with the PP or the Browning Hi-Power. Certain features of the internals are rather PP-like once you get in there, but the takedown fails a full two of my own personal benchmarks for a fully successful field-stripping design:

1) You need a tool, and

2) There is an unintuitive step which you can screw up the whole process by missing or doing wrong.

To illustrate what I mean, here's the pistol all stripped down.

In this photo the resemblance of certain inner workings to the PP becomes more obvious—that fixed barrel, for instance, and the way the recoil spring fits around it. Note that odd metal bit attached at the front of the slide, though, that'll be important in a minute.

Also, see the small black object just above the rear of the slide. That's the disassembly tool. What you have to do with that is slot it into a little plug/recessed button at the rear of the slide (which I tried but couldn't get a decent photo of), where you'd expect the hammer to be on a more conventional design. You use the tooth on the disassembly tool to push a spring catch on that button up, then push the button inward. While holding it there, use your third hand to pull the slide back, but not very far back, and then up, at which point it will disengage from the frame and come off frontwards, again, not unlike the way it does on a PP.

That all seems straightforward enough, and although it's annoying that you need a special tool for it, doesn't sound that traumatic, right? Well, wait until we have to put it back together.

For now, let's take a closer look at that little metal wingus on the slide.

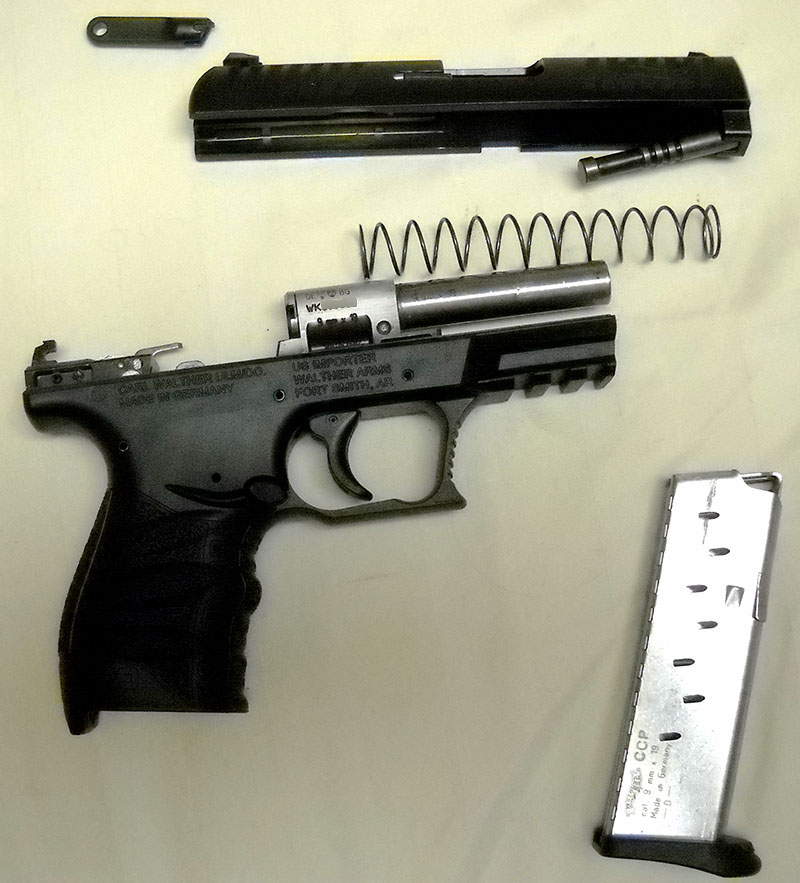

This is the piston that operates the gas-delayed blowback system. It fits into a cylinder in the frame, just underneath the barrel, which is also hard to get a photo of, but I gave it a shot:

What happens is, there's a gas port in the bottom of the barrel, just ahead of the chamber. That port ensures that the gas pressure in the cylinder underneath the barrel is the same as the pressure in the chamber. When the pistol is fired, before the bullet exits the barrel, that gas pressure is very high, and the resulting force acting on the piston holds the slide forward against the stop, preventing it from moving backward and opening the chamber. When the bullet exits the barrel, the gas escapes behind it, the pressure drops, and the piston is freed to move rearward. The action is thus essentially "locked" by gas pressure—exactly the reverse of what happens in a gas-operated action, like that of the M1 Garand or any number of modern service rifles.

It's a clever way of using the very thing that makes a relatively powerful cartridge like 9mm Para dangerous in a small handgun (the high gas pressure) to make the weapon safer for the operator, rather than using a mechanical locking system or resorting to really stiff springs or heavy parts. In fact, it means they could use a lighter recoil spring than you would expect to find, even in a locking action, which makes the CCP slightly but noticeably easier to operate than a full-size service pistol based on the Browning system. Since the gas system is doing all the work of sealing the action, the spring just needs to be able to close the chamber again in a reasonably short amount of time.

However, it's not without its drawbacks. For instance, what happens if the gas port gets blocked? You'll never see that that's happened, since it's deep in the dark internals of the pistol, so the first you'll know about it is when you fire and it doesn't prevent the chamber from opening before the gas pressure drops. I don't know how likely that is to ever happen, but I have to assume it's possible, because you always assume the worst-case scenario is possible. It therefore behooves the CCP owner to be even more dedicated to keeping it clean.

Also, the piston's mount at the front of the slide is hinged, so that there is a bit of vertical play in it. This is surely a good thing in terms of durability, as it lets the mechanism flex rather than break, but it means that reassembling the thing after you take it apart to clean it is an even bigger hassle, because you have to get that lined up on the cylinder pretty much just by feel, while holding back against the recoil spring and keeping the takedown button pressed. The only real way I found to do it was to hold the pistol muzzle-upright and use the plumb-bob method to align the piston vertically.

Oh yes, I mentioned that you need to keep the takedown button pressed (again, with your third hand)? It's not in any way obvious that you have to do that, until you try to reassemble the pistol without doing it and jam the slide inextricably in a partway-back position. If you're misled, as I was, by the general assembly's resemblance to a PP, you will screw this the hell up the first time, because not only will you omit to press the button, you will pull the slide way too far back.

You see, what provides the spring pressure for that takedown button is the same spring that operates the striker, and if it isn't very slightly depressed during the reassembly, or if you pull the slide too far back before bringing it down, or both, that spring will get kinked on one of the other mechanisms in there and jam the works completely up. The slide will not go all the way forward into battery, nor will it come back far enough to lift it off again. You will wrestle with it for ten or fifteen minutes, constantly paranoid that it will suddenly come away from whatever you hung it up on and the recoil spring will fling the slide off the front, and then you will give up, put it gingerly down, go in the other room, and google walther ccp reassembly fail.

There, you will find several pages on gun owner forums saying "it's fucked, even your local gunsmith won't be able to help you, you'll have to send it back to Walther," and once you're done panicking and keep reading, you'll find out what you have to do.

Which is get a screwdriver, feel around in there for the takedown button, and rotate it a quarter-turn clockwise—at which point it will shoot out of the back of the gun, leaving the striker spring hanging halfway out like a broken jack-in-the-box. Then you will have to basically "unscrew" the spring the rest of the way out, which is a bit of a finagle because you have to get the closeoff loop at the end of it around whatever it's hung on. Then you can lift the slide and take the pistol apart again. After which you have to thread the striker spring back in where it goes, find the takedown button from wherever it flung off to (nice catch, Miku), put it back in at its quarter-turned position, get the screwdriver back in there and turn it back upright again so it re-locks, and you're back where you were before you fucked it up, apart from a new entry in your Google search record for the NSA to consider the implications of, and a few new grey hairs.

Now reassemble it again, but this time find a way to keep the button pressed and don't pull it back so far before fitting it back down. Presto. Simple. 200 years of handgun evolution led directly to this moment.

Seriously, you guys, WTF. You're Germans, come up with a better way of doing this.

The awkwardness of its takedown and especially reassembly aside, this is a nifty little gun. Its molded grip fits nicely in the hand, and there's just enough of an extension on the magazine to give the pinky somewhere to sit. The magazine release can be swapped for left-handed shooters, but the directions in the manual make it seem like a bit of a faff, so I'm probably not going to bother doing that, since I'm not going to be taking it into Tactical Reload Situations anyway. The safety is not ambidextrous, but is pretty smooth and easy to operate, and as is usually the case with modern semiautos, the slide release isn't really necessary anyway. It does lock open after the last round, but once you've changed magazines, you can just pull back slightly on the slide and release to chamber the first round.

The sights are surprisingly tiny for such a modern handgun, and they don't have any fancy tritium dots or anything going on, just some white paint. Aftermarket modifications are probably available. It's also got a little section of accessory rail molded into the frame forward of the trigger guard, so you can put a little flashlight or a laser dot sight out there. (Or a tiny, tiny grenade launcher. I'm kidding, they don't make those. As far as I know.)

All in all, not a bad package, but that takedown/reassembly procedure is atrocious, and given the way the action works, anyone who shoots and/or carries it regularly is going to want to take it apart fairly often. Maybe it gets easier once you're used to it, I don't know, but it's unintuitive, and it still fails the "extra tool required" test, which loses major points from me. They can also be a bit hard to find; the MSRP is pretty reasonable, but they're a bit rare, so a lot of dealers are scalping for them and my local guys couldn't even get one from their distributors without paying a markup they were frankly unwilling to pass on to me.

Still, I found mine on the Internet for a decent, uninflated price (modulo the transfer fee at my end, because I am a law-abiding gun nut); it just took a bit of hunting around and a bit of luck with in-stock/out-of-stock. And for that price, I don't regret getting it, even if it is slightly flawed in ways that would probably make it much more annoying if I used it regularly.

--G.

Addendum originally posted March 22, 2017

Got an email today:

Re: Important Safety Recall – MARCH 2017 Walther CCP Pistols

Walther Arms has identified a potential condition in Walther CCP pistols that could potentially cause it to discharge if dropped whether the manual safety is engaged (on) or disengaged (off). The safety of our customers is our paramount concern so we have voluntarily initiated this recall because of the possibility of a drop-fire occurring.

Please do not load or fire your Walther CCP pistol and contact us immediately to arrange to have your pistol upgraded free of charge.

Insufficient drop safety is not the worst thing you can find out is wrong with a gun you own; it's not as if they're saying it's liable to blow up in your face if you shoot it, or it'll spontaneously fire for no evident reason at all, or the like. Still, it's not good. I'm sure Walther drop tested the CCP before putting it into production, which kind of makes me wonder if what's happened here is that one failed some government agency's extra-rigorous drop test standards (the California Department of Justice, for instance, is notorious for specifically testing things until they fail), and Walther is overreacting to forestall litigation.

I don't know that, though; I don't know any more detail than I already gave you. That's just me thinking out loud. Either way, looks like I'm getting an RMA.

I guess this is now one of the guns I can forget about ever selling. :)

--G.

Addendum originally posted April 20, 2017

Well, my CCP returned from its trip to the spa today, as expected. Disappointingly but not surprisingly, Walther included no documentation describing what they actually did to it; the only paperwork included in the box with it was an invoice (for $0.00, because it was classified as a warranty matter). Amusingly, the line item for the work itself is "CCP Upgrade"; it doesn't mention anywhere that it was a recall.

The only outward indication that anything has been done to the pistol is a small mark Walther made on the frame, specifically to indicate for future reference that this individual example has received the 2017 recall repair:

It looks like they put it in a drill press or vertical mill and just kissed the back of the magazine well a little. Pretty effective; that mark isn't likely to wear off, and unless you know what it is and where to look for it, it's unobtrusive.

They also included a couple of nice Walther stickers.

(Priss Morgan totally has a T-shirt with that logo on it. Probably several, in fact.)

--G.

Addendum originally posted April 23, 2017

Well, I took the CCP out for a walk this afternoon, and it seemed to go all right. Whatever modifications Walther made don't seem to have affected the trigger; I hadn't gotten around to taking it shooting before the recall came, but I had dry-fired it a couple of times, and the action seemed to be the same as far as I could tell. They haven't made it bad, in any case; quite crisp for a striker-fired pistol. (This is presumably because it's striker-fired, but still single-action, hence the external safety and lack of a Glock-style trigger-within-trigger.)

I did have a couple of failures in the last magazine's worth of shooting, in the form of one failure to extract and one failure to eject. The first of those didn't even cycle the action enough to reset the striker, so I'm guessing that one, at least, had more to do with the cheapass practice ammunition I was using than the gun itself. It extracted the empty just fine when I opened the action by hand. The second one was a classic "wedged across the ejection port" stoppage (not a stovepipe, but parallel with the port), easily cleared.

At any rate, the recall had nothing to do with the operating system, and I didn't go dropping the pistol on the floor to see whether Walther had succeeded in making it drop safe. :)

Then I came home, took it apart (once again firing the striker spring and takedown button across the room; I will get the knack of that disassembly one day, I swear), bloodied my fingertip on the ejector while swabbing down the action (that little bastard is sharp!), and got it back together without incident. The takedown/reassembly is slowly improving as I practice, but the fact that it requires a tool still loses beaucoup points from me. OTOH, while I had it apart I was able to reverse the magazine release button without too much trouble, apart from the fact that it's one of those processes that kind of require three hands.

Walther USA has provided an amusing video showing someone who is far better at it than I am disassembling, (kinda-halfassedly) cleaning, and reassembling a CCP. I think my favorite part of the video, apart from the casual ease with which the Walther rep gets the gas system to go back together (and even he acknowledges that it's a pain in the ass), is the incongruously heroic music that plays in the background throughout. :)

(These company-produced videos always make it look so easy. The one for the CZ 75 makes it look like all you have to do is move the slide back a little and the disassembly pin will practically come out of its own accord! Ha. Ha. Ha.)

--G.