By the turn of the 20th century, the United States Army had been behind the technological curve in infantry rifle design since basically the Civil War. In that war, despite the fact that metallic cartridges and repeating rifles to fire them were available by 1860, the vast majority of soldiers still fought with single-shot muzzle-loading rifles. Not until long after the war did the U.S. Army at last make the jump to cartridge-firing rifles, but even then the design they selected—the Springfield Model 1873, commonly known as the "trapdoor" Springfield for the way its breechloading mechanism worked—was single-shot only. So was its replacement, the Model 1884.

By that point, smokeless powder was being invented in France and most European armies were on the doorstep of adopting bolt-action repeating rifles of one sort or another: e.g., the Lebel Model 1886 in France, the German 71/84 Mauser (a repeating conversion of the company's single-shot 1871 model) and 1888 "commission rifle", and Britain's 1888 Lee-Metford all came along at around that same time. Mausers of one type or another became the standard, not just in Germany but for much of the world, in the 1880s and 1890s, which is why today one can find references in rifle collecting circles to Turkish Mausers, Spanish Mausers, and practically any other nationality.

Even the United States Navy had adopted a bolt-action repeater, the Remington-Lee (a cousin of the eventual British Lee-Metford and Lee-Enfield), by 1880, albeit in fairly limited numbers. The Army, on the other hand, muddled on with incrementally updated versions of the trapdoor Springfield until 1892, when it finally got around to holding trials for a bolt-action rifle. It had virtually the whole world's selection of such rifles to choose from—by some accounts, there were more than 40 contenders, including the Lee, the Austrian Mannlicher and German Mauser systems, the well-regarded Schmidt-Rubin design from Switzerland, and offerings from every domestic American producer of arms that could come up with anything to send.

Out of all of these options, the Army's ordnance board selected the candidate offered by a pair of Norwegian designers, Ole Krag and Erik Jørgensen. What's most interesting to me about this decision is that only one other army in the world had adopted the Krag-Jørgensen system by that point in time, and it wasn't Norway's (possibly because at the time, Norway was technically still in a faltering political union with Sweden); the Danish Army picked it up in 1889. Norway did eventually adopt a version of the Krag-Jørgensen rifle, but not until after the US did.

The selection of a foreign-designed rifle was... not popular (a few of the American designers passed over in the competition sued the government), but the American Krag rifles were at least produced domestically, by the government armory at Springfield, Massachusetts, which had previously made the "trapdoor" rifles. That meant there was no danger of an international falling-out cutting off the supply of rifles at an inopportune moment (as would have happened with sidearms, for instance, if the Army had adopted the Luger in the 1911 trials and then gone to war with Germany in 1917). Not that the United States was all that likely to have a war with Sweden-Norway, but you never knew in the 1890s. Not a lot of people were expecting a war with Spain either, but we had one in 1898.

It was the Spanish-American War that provided the impetus for the U.S. Army to look for a replacement for the Krag-Jørgensen an inconveniently short time after its adoption. The Spanish forces in Cuba were armed with 1893-pattern Mauser rifles, which rather awkwardly proved to be markedly more effective in combat than the Krag: faster to reload, and firing a cartridge that was both more powerful and had a flatter trajectory than the .30-40 Krag round.

Rightly or wrongly (and there is, as ever, contention about this point), the Krag took a good deal of the blame for the American forces' poor showing at the Battle of San Juan Hill, in which well over 10,000 American and Cuban troops had enormous trouble (and suffered enormous casualties) dealing with a Spanish force perhaps a tenth the size. (The fact that a lot of those guys didn't even have Krags, but instead were still carrying black-powder single-shot Springfields, probably had something to do with it too. I'm just putting it out there.)

At any rate, in the wake of the war, and with US troops in the Philippines having similar difficulties with the local resistance to American "liberation", the Army brass decided it was time to replace the Krag. The criteria were fairly straightforward: what was needed was something as effective as the 1893 Mauser. Engineers at the Springfield Armory put their heads down and considered the problem at length...

... then built an 1893 Mauser. Brilliant, said the Army, we'll take a million. The resulting rifle was standardized as the Model of 1903.

The Mauser company was not so impressed. Neither was the court they sued the US government in, which affirmed that the M1903's design was indeed stolen and ordered that substantial payments be made. This carried on until the United States entered the Great War against Germany in 1917—with the M1903 in many of its soldiers' hands. (But not all; the spike in demand caused by the war prompted the Army to adopt a British-designed rifle, the M1917, to supplement the M1903.)

As an aside, the cartridge this rifle uses is called the .30-'06, despite the fact that it's the M1903 rifle, because the original cartridge developed to go with it (.30-'03) was almost immediately superseded. .30-'03 used a round-nosed bullet, and was adopted roughly 14 minutes before everybody realized that pointed ("spitzer") bullets are ballistically superior in high-powered rifle rounds. .30-'06 was developed to capitalize on that.

The M1903 remained the standard US Army rifle until the semi-automatic M1 Garand was adopted in the 1930s, and was the USMC standard until the Marines got around to adopting the M1 early in World War II. Production timetables being what they were, a lot of the Marines who deployed to the Pacific in 1942 were still carrying bolt-action Springfields.

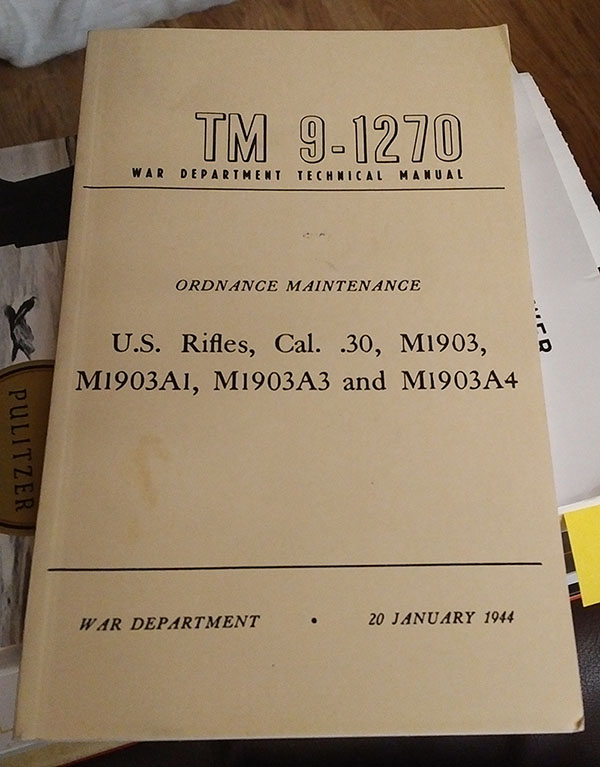

In that same year, Springfield standardized a simpler, easier-to-make version of the rifle as the M1903A3. Its most striking visual difference from the M1903 and M1903A1 (which were mechanically the same, but the A1 had a different style of stock) was the elimination of the original rifle's complicated (and, as these things usually were, wildly optimistic) ladder-style rear sight, which can be seen in front of the receiver in the photo of the original model above, and its replacement with a much smaller and simpler rear sight that could be located on the back of the receiver bridge.

This was not only easier and cheaper to make, it also had the side effect of significantly lenghtening the rifle's sight radius (the distance between the front and rear sight), making it more accurate.

Here's where our particular rifle comes into the picture. Since long before I came into the picture, one of my grandfather's particularly prized guns was an M1903A3 he had acquired while he was in the Army Reserve. It didn't look like one, though. At some point, Gramp had converted it into a hunting rifle, a process known in the trade as "sporterizing". This basically consists of taking an ex-military rifle, cutting down the full-length stock and getting rid of the upper handguard, and adding a telescopic sight. In this particular rifle's case, the end result looked like this:

A while ago, my father and I were visiting Gramp when the conversation came around to rifles he'd used in the Army. Dad asked him what his deer rifle originally was, and he confirmed that it was in fact a 1903 Springfield he'd chopped the stock on. "Kind of wish I hadn't done that now," he mused wistfully.

The conversation moved on to other things, but the remark stuck in my head. When I got home, I started looking around to find out what it would take to convert the rifle back into its original configuration. I figured the hardest part would be finding the wood, but it turned out not to be very difficult. The Civilian Marksmanship Program no longer sells M1903s, but they do still sell newly-produced stock sets for them, in the "Type C" (semi-pistol-grip) configuration, just as the original rifle had been. I ordered one, got hold of a reprint of the WWII-era War Department armorer's manual, and spent a few days scrounging up the small bits and pieces, of which there were quite a lot.

I was hindered slightly in my investigation by the fact that the front scope mount in Gramp's sporter conversion had been attached on top of the base of the barrel, where the original markings were, so I couldn't really read the rifle's serial number. This turned out to be a problem the first time Dad and I sat down to take inventory and see what challenges awaited us as we tried to de-sporterize the rifle.

We'll get to that in a minute, but for now, let's take a closer look at the original conversion.

In order to clear the telescope, Gramp had to replace the bolt body with one featuring a handle with a more radical bend in it. In order for that bolt to be able to close, he had to carve a channel, not just in the stock...

... but also in the metal of the receiver itself:

There was an official sniper's variant of the M1903A3 that was fitted with a telescope (designated M1903A4), but the optic used on the A4 was different from the '60s-vintage commercial model Gramp used on his sporter conversion.

The eyepiece of the original version was much narrower.

Notice, in the photos above, the second channel in the wood. It looks like he originally tried a bolt handle that bent straight down instead of sweeping back like the one he eventually ended up with. There was probably some mixing and matching done during the process, and Springfield rifles had several different bolt handle geometries over the lifespan of the type, so he would have had a number of options to try before finding the ideal setup—assuming he wasn't bending them himself, which is entirely possible.

Farther forward, he got rid of the upper handguard, which (as you can see in the photos of the standard configurations above) was normally held in place by two metal bands. The guard's purpose is to protect the shooter's hand from the heat of the barrel, which tends to get quite hot under the kind of sustained shooting infantry rifles are called on to do. Since hunting rifles aren't fired anywhere near as rapidly, they don't need such things, and so people doing sporting conversions of military rifles usually discard them.

Interestingly, with the hand guard removed, you can tell that the rifle's original makers never expected most of the barrel to be in view; they didn't bother making a finish pass on the lathe when they turned the barrel to its final shape, but left its exterior rough.

Meanwhile, up front, since he wasn't going to be using the two stock/barrel bands, Gramp filled in the channel for the rear band's retention spring.

He also cut down the stock to remove most of the wood ahead of where that rear band had been.

Turning back for a moment, I mentioned that not being able to tell the serial number was a problem when Dad and I first looked into restoring this rifle. That's because the stock set I bought for it was for the M1903A1, not the A3. The main difference between them is the location of the rear sight: because the A3 version doesn't have that giant ladder sight mounted at the base of the barrel, the hand guard needs to be longer to cover that part of the barrel.

Fortunately, I was able to get hold of a replacement A3 hand guard elsewhere on the Web, and the extra piece of hardware needed to mount it (a metal ring that fits at the barrel base, to hold the tab at the back of the hand guard down). I also had to track down an A3 bolt body with the original handle angle on it, so that we wouldn't have to channel the new stock. The need to track down a few extra parts held us up for a little while.

Nevertheless, we persevered, and a little while ago we blocked out an afternoon to do the job. Our workspace was my kitchen table, which is, leaving aside the rifle parts and the stray Coke Zero bottle, the cleanest it's been for years in this photo.

Dismounting the scope, pulling the bolt from the rifle, and then removing the barreled action from the stock were all pretty simple operations, and in this picture it looks like installing the action in the new one will be as simple. But appearances can be deceiving when you're working with these things.

Our first order of business after disassembly was to get the striker mechanism out of the original bolt and replace it in the new bare-bones bolt body. While we had them apart, I decided to get a couple of comparison photos. The original bolt, in the white (possibly it was finished once and the original finish has just worn off), is on the left; the new one, in the original-spec dark grey Parkerizing, is on the right, with the dismounted striker assembly between them. (We've already moved the extractor to the new bolt.)

In the lower shot, you can get a clear view of the difference in handle angle between the two. The replacement stands considerably clearer of the rifle's body before taking the downward bend.

Once we had the bolt refitted, we could set it aside and work on the main rifle. The first thing to do was take off the scope mounts. These were held on with three tiny screws, two on the front and one on the rear mount. Simple! Except these screws had been seriously tightened down in about 1965 and not touched since. Removing them was physically the hardest part of the operation, involving liberal applications of Liquid Wrench and a great deal of swearing. After which we discovered that one of the forward holes actually goes all the way through, so we put the screw back in it to keep crud from getting into the action.

(It's not in the pressure-bearing part of the barrel, but rather in the area just behind the chamber, so it shouldn't be a safety issue, but it's annoying.)

On the plus side, getting the front mount off meant we could get a good look at the markings, or at least what of them hadn't been obliterated by drilling the screw holes.

The damaged line originally said MODEL 03-A3. Remington made M1903, M1903A3, and M1903A4 rifles under contract; in fact, they kept making them for a couple of years longer than the actual Springfield Armory. Springfield converted to all M1 Garand production in 1942, while Remington kept making A3s and A4s until 1944. A check on the serial number indicates that this one was made in April 1942. (By a weird coincidence, that is the same month that my Springfield Garand was manufactured!) This may also go some way toward explaining the lack of fine finish work on the barrel—wartime production tended to be a bit more expedience-oriented. We will see evidence supporting this surmise in a bit.

Also visible in that photo is the metal ring to hold down the rear tab of the hand guard (that black band on the right side). Take note of that, it'll be important in a minute.

Fitting the barreled action into the new stock took more work than we were expecting. Possibly because these things are never quite as interchangeable as they look like they should be, and possibly because the CMP's new-made stock sets are technically for the A1 model, there was a bit of fine-tuning required before everything would line up properly. For instance, the hole for the frontmost of the two main screws that hold the action, stock, and trigger guard/magazine assemblies all together wasn't quite right:

Note how there isn't full clearance all the way around. We had to take a Dremel tool with a small grindstone fitted and channel that out a bit before we could get the forward mount to screw together properly.

Similarly, the action wouldn't sit quite far enough back in the stock as provided. When Dad and I investigated, we found that the tang at the back of the action had a slight radius to the underside of it...

... while the place where it's meant to sit had a squared-off "step" in it.

I forgot to get a photo of the mod we made to that part in order to fit them together, but it was in a similar vein.

With that taken care of, it was time to fit the hand guard and the hardware for retaining it. At that point we realized we had omitted the ring (shown in the markings picture above) and had to take the stock back off to install it... and then discovered that neither it, nor the forward of the two barrel bands, nor the nose band that goes ahead of that, would fit over the front sight.

So, that had to come off. This was accomplished by drifting out the lower of the two pins, then driving the front sight ring off the front of the barrel with a brass hammer. (Notice that the lack of a finish pass on the lathe extends all the way to the muzzle, suggesting that "it'll be covered by the hand guard" wasn't the only reason this rifle's makers didn't lavish a lot of fine finish work on it.) That would have been fine, except that I didn't have a small enough punch in my toolbox, so we had to go to the hardware store and get one. It's always something.

As an aside, this provided an interesting deductive insight into the process by which Gramp did the original operation. It was fairly obvious he hadn't bothered to take the front sight off, remove all that hardware, and then put it back on. He was putting a scope on the rifle anyway, he wouldn't have had any reason to put the front sight back. This implies that he most likely just cut the bands off and threw them out, because it was the quickest and simplest way to do it.

At any rate, once Dad and I had the front sight off, we could fit the ring, put the stock back on, then put on the hand guard and start attaching the bands. The rearward band, which also is the mounting point for the front sling swivel, went on easily.

Note the spring, the channel for which was puttied in as part of the original stock's sporter conversion. That's just there to keep the band from working its way off accidentally if the screw tightening it on happens to loosen up.

Ahead of that, the smaller forward (sometimes called "upper") band also went on without a hitch. This one supports a stacking hook, similar to those found on many other WWI-vintage rifles.

Ahead of that is the nose band, which is mostly there to have the bayonet lug on it.

This turned out to be a royal pain in the ass to put on, because that screw has to go in one side, go all the way through a hole in the stock (visible in the previous photo), then screw into a hole on the far side of the metal band, and getting that to line up so the threads would start was much harder than it sounds like it should've be. For a while we thought the part (a modern reproduction) might not have been made quite right, but after fiddling with it over and over for what seemed like an hour or so, we finally got it, after which we were able to reinstall the front sight without incident.

That left only a few finishing touches, most notably the rear sight. The original had been removed to make way for the rear scope mount; I acquired a replacement along with the other bits and pieces, and once the scope mount was out of the way, it was a simple (if not necessarily easy) matter of driving the new one onto the (luckily still intact) dovetail atop the receiver bridge.

With that done, we just had to transfer the buttplate from the old stock, attach a new-old-stock rear sling swivel, and pop on a reproduction WWII-era web sling, and voilà—one de-sporterized M1903A3 rifle! About the only thing that's missing now is a bayonet.

For the record, the intent here was never to pass this rifle off as original; simply to restore it as close to original condition as we could. On close inspection, it's obvious that the hand guard doesn't match the stock, the hardware is mostly new, and the stock is an obvious reproduction. It's even marked with a CMP cartouche, a nice little touch reminiscent of the markings showing who made the original ones.

We haven't shown it to Gramp yet; the old folks' home where he lives now doesn't really having firearms on the premises. (He apparently got Spoken To about it when I brought my Garand up to show him last year.) So that'll have to wait until the weather is a bit better, Dad's done with the classes he's taking, and we can get Gramp down here to see it.

It's not perfect, and there are still a couple of little things to do. The lower band we used doesn't seem to fit very well (it might be an A1 band, I'm not sure if they're different); I've ordered a new-old-stock A3 one to try instead, but it's not here yet. We might try to touch up the finish mismatch between the two pieces of wood. And because we replaced the sights and the stock, and don't really know anything about the dark art of bedding a rifle stock, I'm sure it's hilariously out of zero. For our present purposes, though, that's not really important.

What's important is that my father and I spent an afternoon doing detective work together about something his father did probably 50 or more years ago, and making a Thing, and restoring a historic item to something more akin to its original form. And undoing a thing an 87-year-old man recently said he regretted doing. All of which, you ask me, is a pretty good way to spend an afternoon.